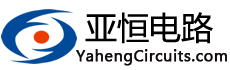

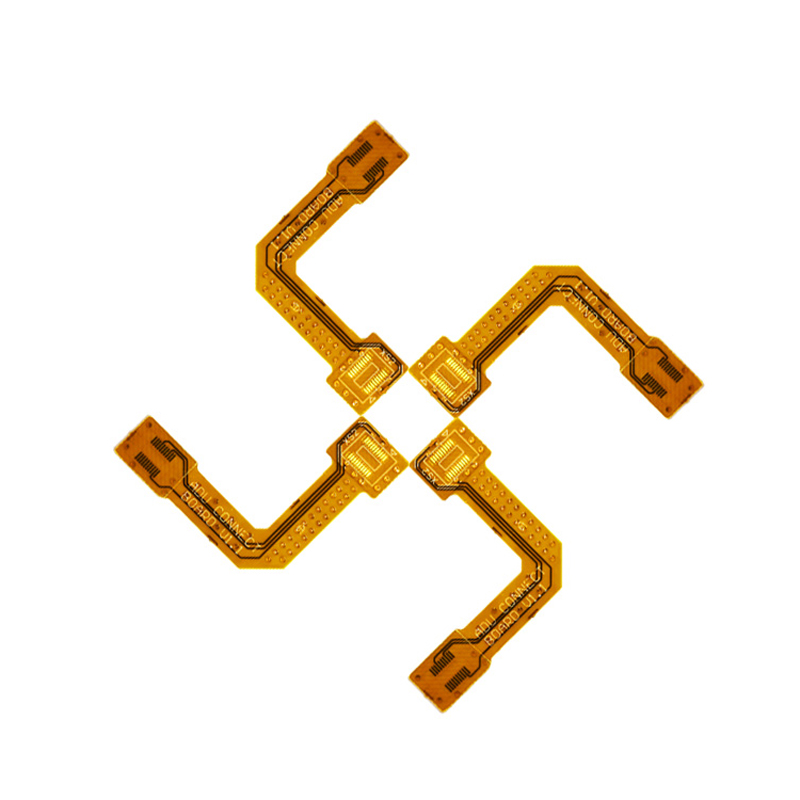

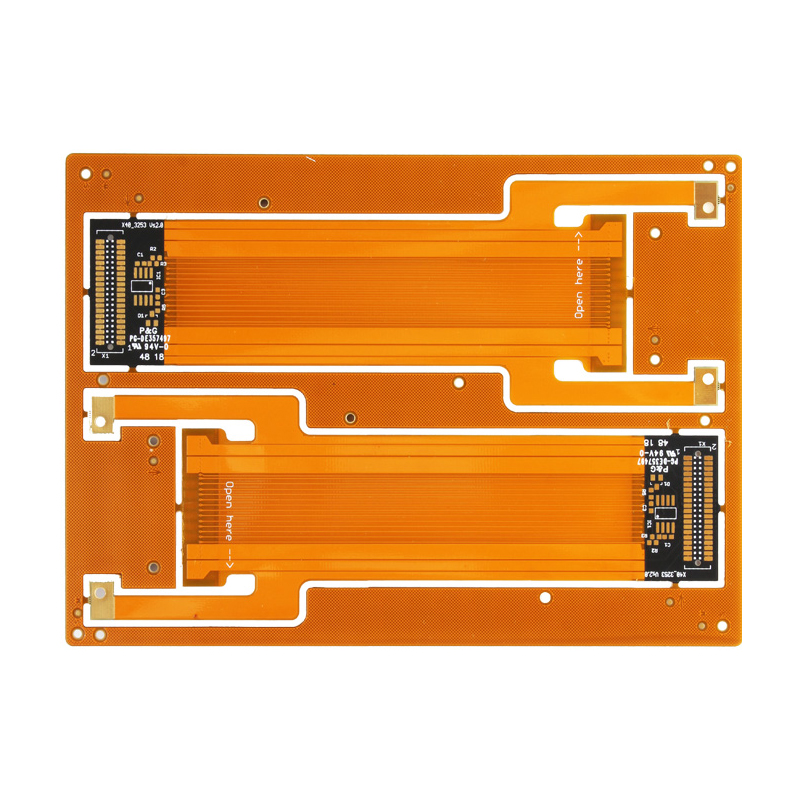

Multilayer flexible printed circuit board

The multi-layer flexible circuit board is composed of multiple inner layers and two outer layers. The surface treatment adopts the immersion gold process with high solderability (environmental protection), and adopts high-quality cover film, which is heat-resistant and radiation-resistant. The product has a wide range of applications and is suitable for many electronic products with high precision and high requirements.

1. Substrate

The use of non-adhesive substrates is different from adhesive substrates in that its bonding method is to use a hot press to press the copper foil and substrate together. In comparison, its flexibility, copper foil and substrate The parameters such as the bonding force and the flatness of the pad are better than those of the glued flexible board. However, its price is relatively high, and it is generally only used in occasions with relatively high requirements.

2. Copper foil

Rolled copper foil is used, which has better bending properties. The unit price of rolled copper foil is more expensive than that of electrolytic copper foil. Rolled copper foil has tight molecules and good flexibility.

3. Insulation material

The insulating material is PI, and PI is generally used as the base film, that is, the base film in the base material and the protective film. PI has the characteristics of high temperature resistance and can be welded, and its flexibility, dimensional stability, insulation properties, heat resistance, electrical properties and mechanical properties are very good.

The multi-layer flexible PCB Product Advantages

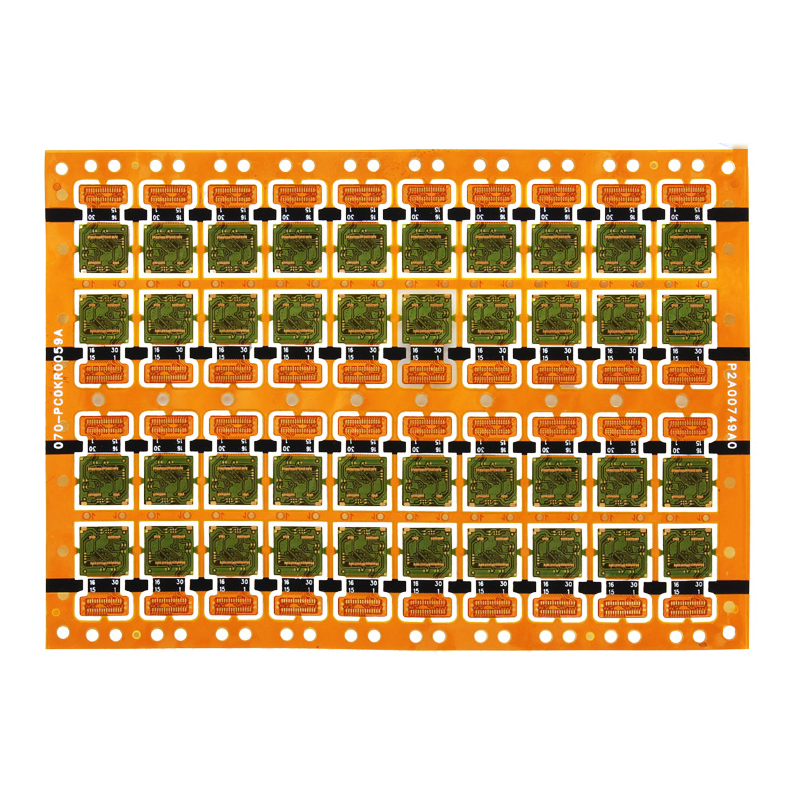

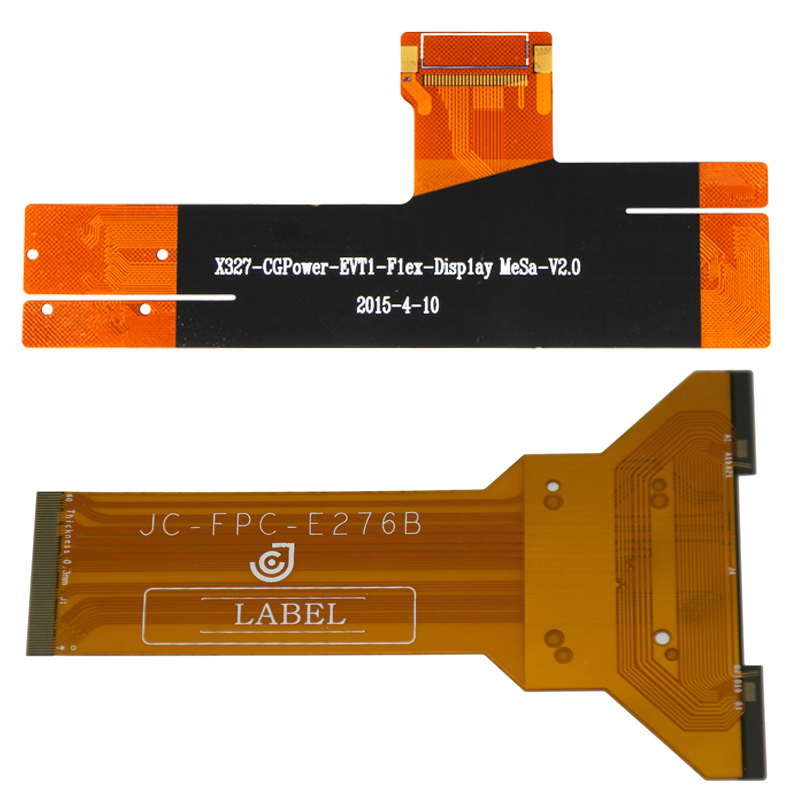

1. Flexibility

A significant advantage of using FPC flexible board is that it can more easily route and connect in three-dimensional space, and can also be rolled or folded for use. As long as it is curled within the allowable radius of curvature, it can withstand thousands to tens of thousands of uses without damage.

2. Increased reliability

When using the FPC flexible board to install and connect, because it can be wired on the three planes of X, Y, and Z, the transfer interconnection is reduced, the reliability of the whole system is increased, and the inspection of faults is convenient.

3. Controllability of electrical parameter design

According to the requirements of use, designers can control capacitance, inductance, characteristic impedance, delay and attenuation, etc. when designing FPC flexible boards. Can be designed to have the characteristics of a transmission line. Because these parameters are related to wire width, thickness, spacing, insulation thickness, dielectric constant, loss tangent, etc., this is difficult to achieve when using wire and cable.

Frequently Asked Questions

Q: I have a multi-layer flexible circuit board, can 0.2mm vias be made?

A: Yes.

Q: Can the line width and line spacing of 0.08mm be produced?

A: Yes

Q: Can your fpc multilayer board do impedance control?

A: Hello, we can do impedance control.

Q: How long does it take for the multi-layer flexible circuit board proofing?

A: Usually 8-10 days

The above are some descriptions of some parameters, advantages, details, and frequently asked questions of multi-layer flexible circuit boards compiled by Xiaobian. I hope it will be helpful to everyone when purchasing multi-layer flexible circuit boards.

Yaheng Circuits produces prototype, mid and high-volume double sided PCBs, with a copper foil thickness ranging from 1 to 20 ounces. Operating temperatures range from 130 C to 230 C, depending on base material type. Double sided PCBs are available with many surface finishes including Organic Surface Protectant (OSP), Immersion Silver, Immersion Tin, Electroless Nickel Immersion Gold (ENIG) and either leaded or lead-free Hot Air Solder Level (HASL).

Yaheng Circuits is not only trying to give customers a good product but also pay attention to offering a complete and safe package. And here we prepare some personalized services for all the orders.

Common packaging:

PCB: Vacuum packaging with carton box

PCBA: ESD packaging with carton box

Shipping:

1.Confirming your shipping address is correct before delivery

2.Orders processed timely after the payment verification

3.Professional package. No worry about goods breakage.

4.Service transit time is upon different carrier, may vary particularly during holiday.