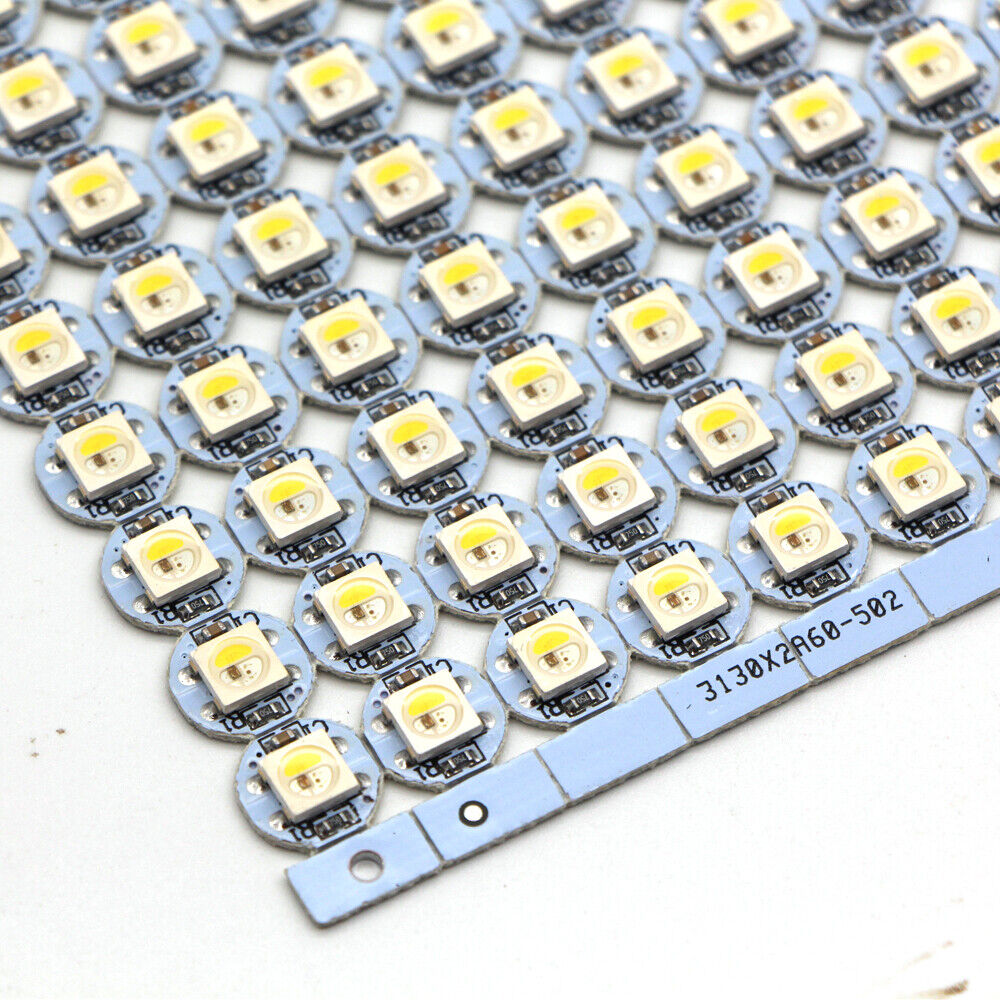

LED PCB

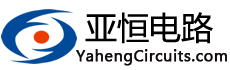

LED stands for Light-Emitting Diode, which is a semiconductor diode. LEDs are soldered onto PCBs and are equipped with a chip that generates light through electrical connections. A heat sink and a ceramic base are used to connect the chip. Undoubtedly, LED PCBs are the core of LED lighting. An LED PCB tends to generate a significant amount of heat, which is challenging to dissipate using traditional methods. Metal core PCBs, especially those made of aluminum, are widely used in LED applications due to their strong heat dissipation capabilities. Typically, an aluminum PCB includes a thin layer of thermally conductive material, which efficiently transfers and dissipates heat compared to traditional rigid PCBs.

Currently, surface mount packaging is the most widely used form of LED packaging in LED applications. Generally, the light emitted by a single LED component is limited. Therefore, a luminaire will utilize multiple LED components to achieve sufficient brightness. Similar to other semiconductor devices, PCBs provide the optimal means of electrical connection for LED components. PCBs with LED components are commonly referred to as "LED PCBs."

Advantages of LED PCB:

When it comes to the advantages of using LED PCB, well there are plenty of them and we are now going to mention a few so that you know about the application too.

Lower Power Consumption: Replacing incandescent bulbs with LED lights can reduce power consumption by over 80%.

Longer Lifespan: LEDs typically have a lifespan of over 20,000 hours, allowing for continuous usage for up to 3 years, which is 25 times longer than incandescent bulbs. This not only saves costs but also reduces the frequency of replacement.

Higher Efficiency: Incandescent bulbs emit a significant amount of heat, while LEDs can reduce it by up to 20%. This means that unnecessary heating can be reduced even when using higher-power LED lights.

Smaller Size: Due to their compact size, LED lights can come in various dimensions, making them applicable in different locations. Manufacturers can incorporate LEDs into anything, whether it is electronic devices, automobiles, traffic signals on roads, or signage.

Environmentally Friendly: Unlike other types of bulbs, LED lights do not contain mercury. Therefore, LEDs have a smaller environmental impact and are easier to dispose of or handle.

Applications of LED PCB

PCB LED lights offer excellent energy efficiency, low cost, and maximum design flexibility, making them suitable for many lighting applications.

Telecommunications: LED indicator lights and displays are commonly used in telecommunications equipment due to their mechanical compatibility and excellent heat dissipation capabilities. Therefore, aluminum-based LED PCBs play a crucial role in in their applications.

Automotive: Aluminum PCB LEDs are also used in automotive indicator lights, brake lights, headlights, and other applications. Several factors make aluminum PCBs ideal in the automotive industry, including durability and competitive pricing.

Computers: LED displays and indicator lights are increasingly popular in computer applications. Due to the thermal sensitivity of computer components, aluminum PCB LEDs provide an ideal solution. In addition to LED applications, aluminum PCBs are also used in computer components such as power supplies and CPU boards due to their heat dissipation and transfer capabilities.

Computers: LED displays and indicator lights are increasingly popular in computer applications. Due to the thermal sensitivity of computer components, aluminum PCB LEDs provide an ideal solution. In addition to LED applications, aluminum PCBs are also used in computer components such as power supplies and CPU boards due to their heat dissipation and transfer capabilities.

Medical: Lighting tools used in surgical procedures and medical examinations often utilize high-power LED lights, typically using aluminum PCBs. This is mainly due to the durability and heat dissipation capabilities of aluminum PCB LEDs, ensuring the proper functioning of medical equipment, regardless of the number of patients cycled through medical facilities. Apart from lighting tools, medical scanning technologies frequently employ aluminum PCBs as well.

As a PCB manufacturer with more than a decade of experience, we can provide LED PCB fabrication, components purchasing and assembly. You just need to upload your customized Gerber file and BOM for us to quote. And then you can check our quotation and decide to buy from us or not, it is also acceptable that you supply us the parts for assembly if you want.

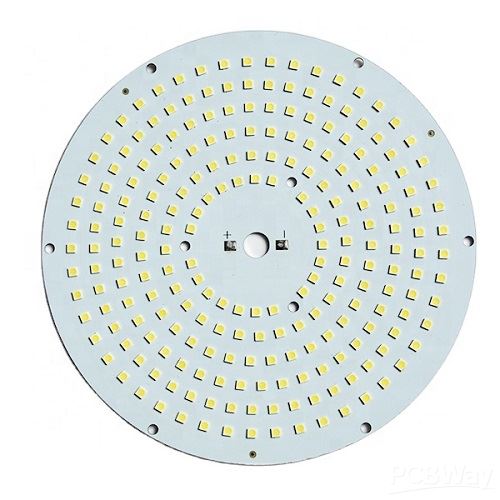

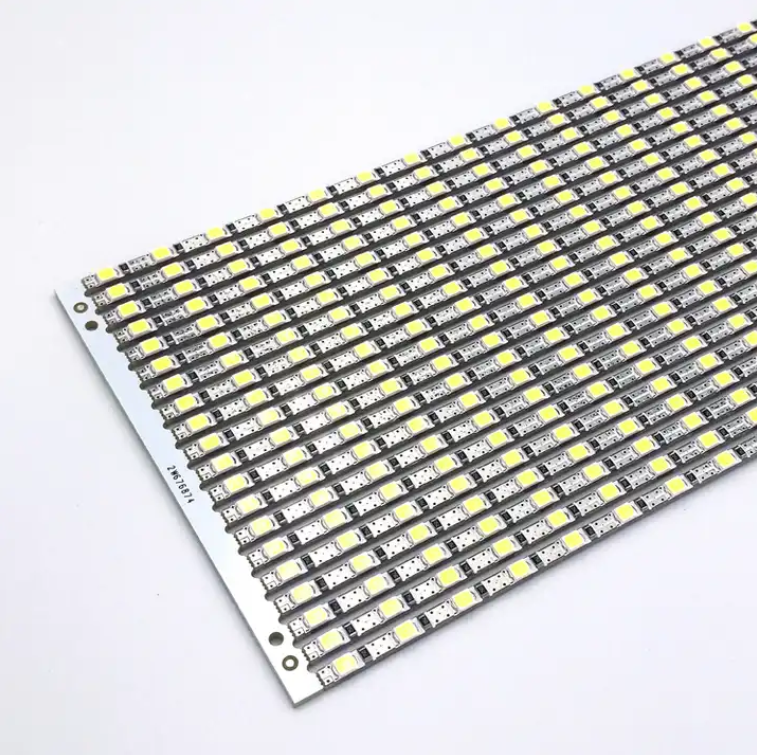

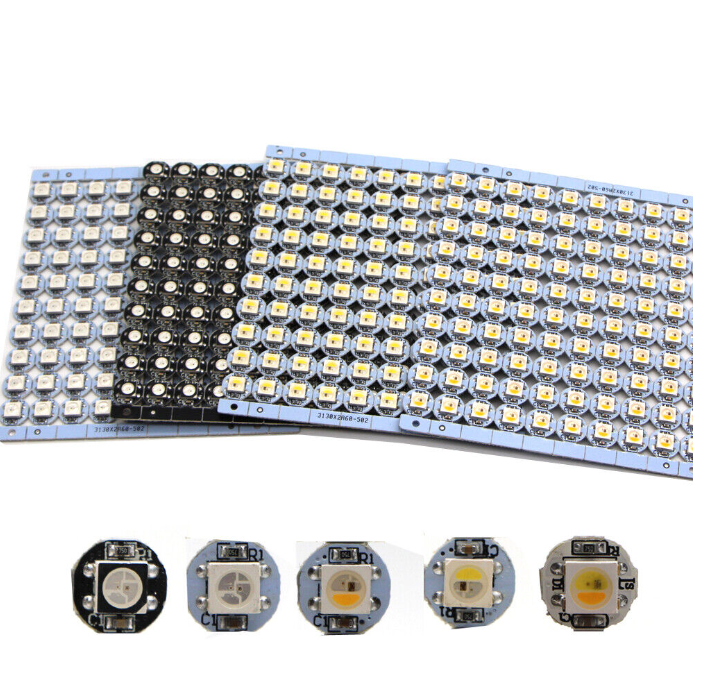

LED Strip PCB:

An LED strip PCB, also known as a printed circuit board, is a specialized circuit board designed for use with LED light strips. LED strips consist of a series of individual light-emitting diodes (LEDs) that are mounted on a flexible or rigid strip of material. The PCB serves as the base or substrate onto which the LEDs are soldered, providing electrical connections and support.

The LED strip PCB typically has copper traces or conductive pathways that connect the LEDs in a specific configuration, allowing for the flow of electrical current to power the individual LEDs. The PCB also provides structural stability and protection for the LEDs, as well as thermal management to dissipate heat generated by the LEDs.

LED strip PCBs come in different forms depending on the type of LED strip. For flexible LED strips, the PCB is usually made of a flexible material like polyimide, which allows the strip to bend and conform to different shapes and surfaces. Rigid LED strips, on the other hand, use a rigid PCB material like fiberglass or aluminum, providing a more stable and durable construction.

LED strip PCBs may also feature additional components such as resistors, capacitors, or integrated circuits (ICs) to regulate voltage, control brightness, or enable various lighting effects. These additional components are often mounted directly onto the PCB.

Overall, LED strip PCBs play a crucial role in providing electrical connectivity, support, and thermal management for LED light strips, allowing for easy installation and integration into various lighting applications.