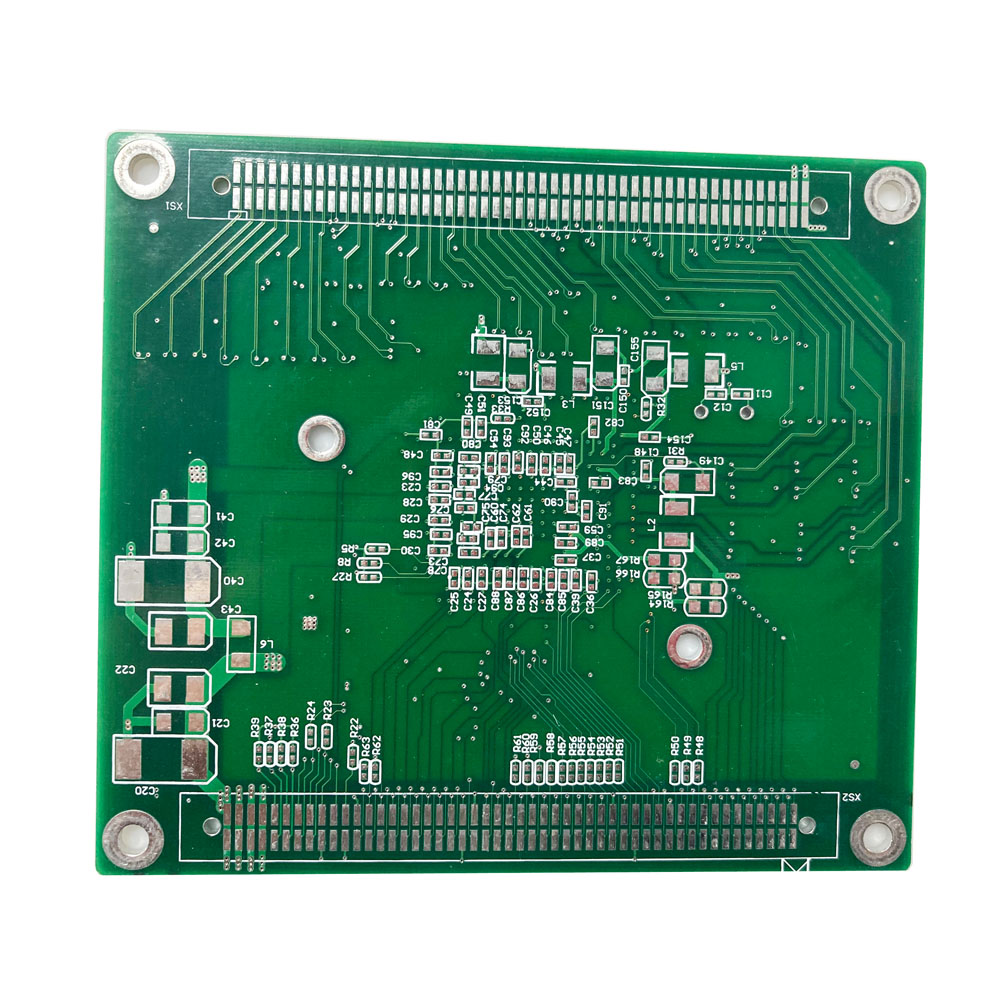

Single Sided PCBs

Single Sided PCBs are the least complicated type of PCB. They are made of a single conductive layer of copper above the substrate.

The electronic components are then soldered or mounted on to one side of the board and the etched circuit can be seen on the other side of the board. This type of PCB has been around for many years and is still the most widely used compared to double sided boards and multilayer boards, if considered by volume alone. Single layer boards are the most cost-effective platform in the industry because they are easily designed and quickly manufactured. In PCB manufacturing, a single sided PCB is made using one layer of insulating dielectric, laminated with copper. Soldermask is usually applied on top of the copper to insulate from the outside world.

Yaheng Circuits produces prototype, mid and high volume single sided PCBs, with a copper thickness ranging from 1 to 20 ounces. Operating temperatures range from 130 C to 230 C, depending on base material type. Single sided boards are available with many surface finishes including Organic Surface Protectant (OSP), Immersion Silver, Immersion Tin, Electroless Nickel Immersion Gold (ENIG) and either leaded or lead-free Hot Air Solder Level (HASL).

FAQ

Q: What is needed for PCB/PCBA quotation?

A: For Bare PCB project, please provide Quantity, Gerber file and specification like material, surface finish treatment, copper thickness, board thickness, soldermask color and silkscreen color and other special specs. For PCBA project, please provide above information as well, and BOM list, pick and place file. If you need turnkey service include programming and functional testing etc, kindly contact us for more details.

Q: Are my files safe?

A: Your files are held in complete safety and security.We protect the intellectual property for our customers in the whole process.. All documents from customers are never shared with any third parties. We are willing to sign NDA effect by customer side local law and promising to keep customers data in high confidential level.

Q: What’s your minimum of quantity(MOQ) ?

A: There is no MOQ in Yaheng Circuits(PCB/PCBA).We are able to handle small as well as large volume production with flexibility.

Q: How to calculate the shipping cost?

A: The shipping cost is determined by the destination, weight, packing size of the goods. Please let us know if you need us to quote you the shipping cost.

Q: What other service do you have?

A: We mainly focus on PCB+Assembly+Components sourcing service. Additionally, we can also provide programming, testing, cables, enclosure assembly service.

Q: Can we inspect quality during production?

A: Yes, we are open and transparent on each production process. We Welcome you visit our factory to inspect our production process.

Q: What is your testing policy and how you control the quality?

A: Regarding to PCB samples, usually tested by flying probe; for PCB Volume over 3 square meters, usually tested by Electrical fixture which is faster. As to PCBA production, there are automated optical inspection (AOI) for each batch, X-ray inspection for BGA parts, first article inspection(FAI) before mass production.

>>>>>>Kindly click here send your inquiry, we will reply you within 12 hours even faster:)

Inner: vacuum packing or Anti-static package,

Outer: export carton

or according to the customer's requirement.