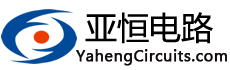

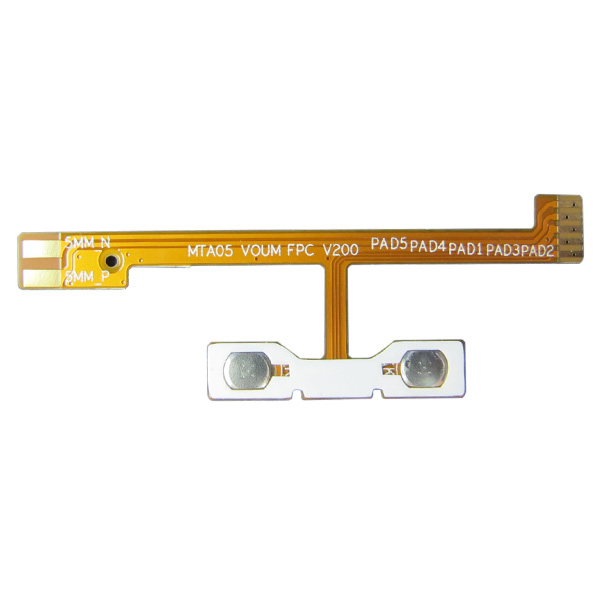

FPC flexible circuit with 3M stiffener & dome

3M Stiffener Flexible printed circuits

Flexible printed circuits have become established in recent years as a medium for circuits.

The main users of flexible printed circuits are the technological sectors which need the following characteristics and benefits:

Implementation of compact, complex assemblies which minimise size and weight

Dynamically and mechanically robust when bent

Defined characteristics of the circuit systems on the circuit board (impedances and resistances)

Reliability of the electrical connections by minimising the number of connections between the modules

Saving connectors and wiring, also cost-saving by lowering the costs for component placement and assembly

2. Materials

Flexible base material: As a base material, Yaheng Circuit uses exclusively polyimide film which, compared to the alternative PET and PEN films has the advantage of a high processing temperature range, unrestricted solderability as well as the large operating temperature range. Depending on the requirements for the product and process, differing versions of film are used.

| Polyimide thickness | 25 µm, 50 µm, 100 µm | Yaheng Circuits standard: 50 µm |

| Copper | Single or double sided | |

| 18 µm, 35 µm, 70 µm | Yaheng Circuits standard: 18 µm or 35 µm | |

| Rolled copper (RA) | Suitable for dynamic, flexible applications | |

| Electrolytically deposited copper (ED) | Low elongation after fracture, only suited for static and semi-dynamic applications | |

| Adhesive systems | Acrylic adhesive | For dynamical, flexible applications, not UL 94 V-0 listed |

| Expoy adhesive | Limited dynamic flexibility, UL 94 V-0 listed | |

| Adhesive free | Yaheng Circuits standard, high flexibility, chemical resistance, and is UL 94 V-0 listed |

High quality fpc pcb board:with high speed transmission current stable,flexible,easy to install,good insulation.

Flexible pcba board:export led pcb board,PI material,Electrolytic copper,ultra-thin thickness,can be bent at will.

Double side flat cable flex pcb manufacturer:connection line+PI reinforcement+tin spraying process.

SINGLE SIDE FLAT CABLE BOARD:Reinforcing material Pl, auxiliary

material: conductive adhesive, shielding film,resistance to winding capacity of more than 150,000 times.

| Item | 3M Stiffener Flexible PCB |

| Max Layer | 8L |

| Inner Layer Min Trace/Space | 3/3mil |

| Out Layer Min Trace/Space | 3.5/4mil |

| Inner Layer Max Copper | 2oz |

| Out Layer Max Copper | 2oz |

| Min Mechanical Drilling | 0.1mm |

| Min Laser Drilling | 0.1mm |

| Aspect Ratio(Mechanical Drilling) | 10:1 |

| Aspect Ratio(Laser Drilling) | / |

| Press Fit Hole Ttolerance | ±0.05mm |

| PTH Tolerance | ±0.075mm |

| NPTH Tolerance | ±0.05mm |

| Countersink Tolerance | ±0.15mm |

| Board Thickness | 0.1-0.5mm |

| Board Thickness Tolerance(<1.0mm) | ±0.05mm |

| Board Thickness Tolerance(≥1.0mm) | / |

| Impedance Tolerance | Single-Ended:±5Ω(≤50Ω),±10%(>50Ω) |

| Differential:±5Ω(≤50Ω),±10%(>50Ω) | |

| Min Board Size | 5*10mm |

| Max Board Size | 9*14inch |

| Contour Tolerance | ±0.05mm |

| Min BGA | 7mil |

| Min SMT | 7*10mil |

| Surface Treatment | ENIG,Gold Finger,Immersion Silver,Immersion Tin,HASL(LF),OSP,ENEPIG,Flash Gold;Hard gold plating |

| Solder Mask | Green Solder Mask/Black PI/Yellow PI |

| Min Solder Mask Clearance | 3mil |

| Min Solder Mask Dam | 8mil |

| Legend | White,Black,Red,Yellow |

| Min Legend Width/Height | 4/23mil |

| Strain Fillet Width | 1.5+0.5mil |

| Bow & Twist | / |

The Advantages of Rigid Flex PCB Technology

While this type of flexible circuit may be more expensive to design and produce, it does offer a number of important advantages. For instance, the reduced size makes it easier to fit more components into a smaller space. This can actually help to lower overall system costs. Additionally, because they require the need for fewer interconnects and related parts and components, these flexible circuit board can also prove to be more reliable and require less maintenance in the long run.

As with all types of flexible circuit boards, the rigid flex printed circuit boards will perform well in even the harshest environments, especially those featuring extreme heat. A rigid flex board is also easy to test, making it well-suited for prototyping.

Rigid Flex PCB Solutions of the Highest Quality

Currently, Yaheng Circuits has served companies in industries such as medical, telecommunications and manufacturing with our superior quality rigid flex PCB manufacturing services. We have an in-house quality control department to ensure your boards fabricated and assembled properly - we also guarantee the quality of all parts and components. Our engineers will even perform a Design for Manufacture (DFM) check at no additional charge.

Our experience and technical expertise enables us to develop custom rigid flex circuit boards for any specific applications.