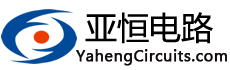

4 layer rigid flex circuit board for automotive products

This is a 6 layer rigid-flex circuit board for automotive electronics. The rigid flex PCB is widely used in medical technology, sensors, mechatronics or in instrumentation, electronics squeezes ever more intelligence into ever smaller spaces, and the packing density increases to record levels again & again.

Product Details

| Layers | 4 layers rigid, 2 layers flex |

| Board thickness | 4 layers rigid, 2 layers flex |

| Material | Shengyi S1000-2 FR-4(TG≥170℃) + Polyimide |

| Copper thickness | 1 OZ(35um) |

| Surface Finish | (ENIG 3μm) Immersion gold |

| Min Hole(mm) | 0.22mm |

| Min Line Width(mm) | 0.15mm |

| Min Line Space(mm) | 0.18mm |

| Solder Mask | Green |

| Legend Color | White |

| Packing | Anti-static bag |

| E-test | Flying probe or Fixture |

| Acceptance standard | IPC-A-600H Class 2 |

| Application | Optics device |

Introduction

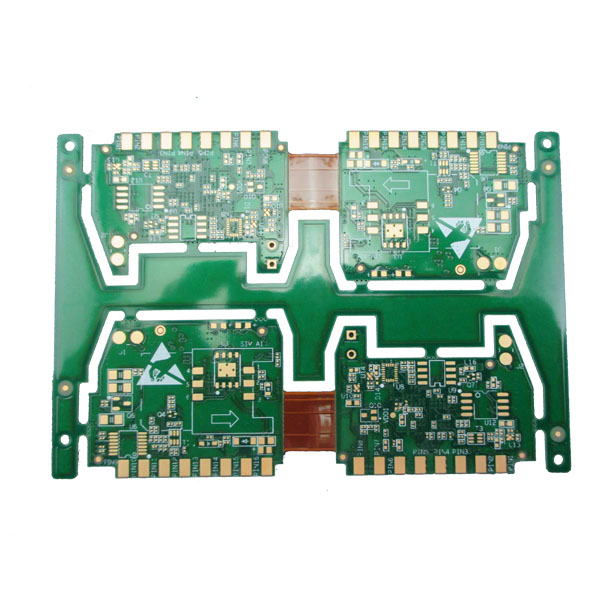

Rigid-flex PCB means hybrid systems, which combine the characteristics of rigid and flexible circuit substrates in one product. Whether in medical technology, sensors, mechatronics or in instrumentation, electronics squeezes ever more intelligence into ever smaller spaces, and the packing density increases to record levels again & again. Using flexible PCBs and rigid-flex printed circuit boards, whole new horizons open up for electronic engineers and designers.

Advantages of rigid-flex PCB

l Reduction of weight and volume

l Defined characteristics of the circuit systems on the circuit board (impedances and resistances)

l Reliability of the electrical connections due to reliable orientation and reliable contacts as well as savings on connectors and wiring

l Dynamically and mechanically robust

l Freedom to design in 3 dimensions

Materials

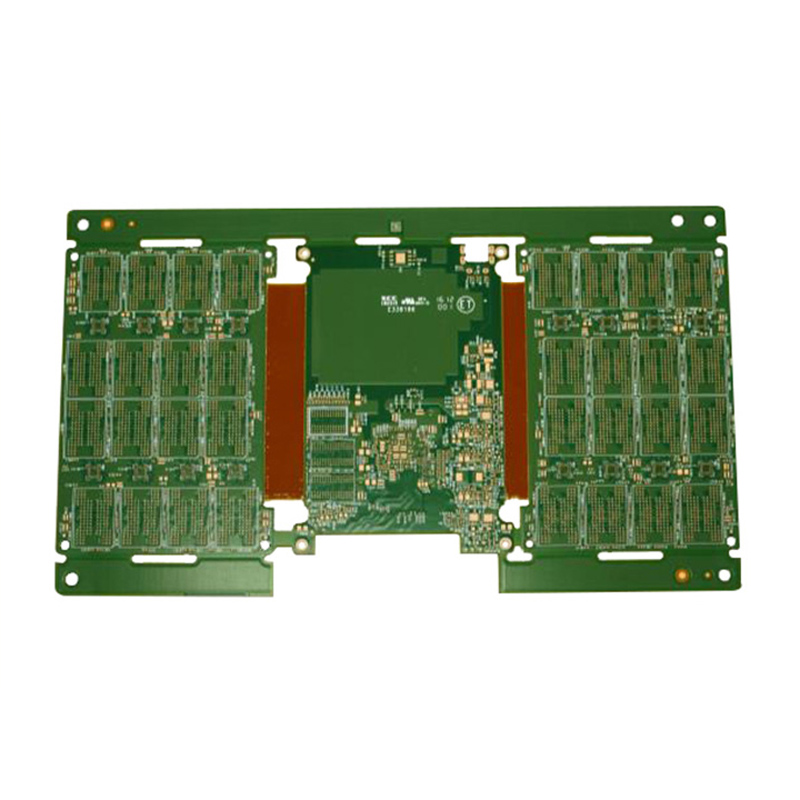

Flexible base material: Flexible base material consists of a foil made of flexible polyester or polyimide with tracks on one or both sides. Yaheng Circuits uses polyimide materials exclusively. Depending on the application, we may use Pyralux and Nikaflex made by DuPont and the glueless flexible laminates in the FeliosFlex series made by Panasonic.

Apart from the thickness of the polyimide, the materials mainly differ in their adhesive systems (glueless or on epoxy or acrylic basis) as well as in the copper quality. For comparatively static bending applications with a low number of bend cycles (for assembly or maintenance) ED (electro-deposited) material is adequate. For more dynamic, flexible applications RA (rolled annealed) materials must be used.

Materials are selected on the basis of the product and production specific requirements, and the datasheets of the materials used can be requested as required.

Adhesive systems: As a bonding agent between the flexible and the rigid materials, systems using adhesive on an epoxy or acrylic basis (which is still capable of reacting) are used. The options are as follows:

Composite film (polyimide film coated on both sides with adhesive)

Adhesive films (adhesive systems poured onto a paper base and covered with a protective film)

No-flow prepregs (glass mat/epoxy resin prepreg with very low resin flow)

Rigiflex is one of the leading manufacturers of 14 layer rigid-flex PCBs. These PCBs are used for applications, which demand extreme precision and tight tolerances. Over the years, we have helped clients by designing and providing compact sized 14 layer rigid-flex PCBs. These circuit boards comprise flexible inner layers, which are attached using a prepeg film, which resembles to a multilayer flexible circuit. These rigid-flex PCBs are equipped with a board internally, externally, or both – as needed by the circuit.

The rigid components of these circuit boards are utilized for high density device boards. Additionally, flexible circuits allow narrow lines, thereby supporting high density device population. The combination of rigid boards and flexible circuits allow us to offer streamline design, thereby reducing package weight and size.

Typically, these circuit boards are made from FR4 material. We can also provide them in exotic materials such as Rogers Ultralam 2000, Rogers RO4350, Arlon AR350, Nelco 4013, as well as several metal core materials. We use various types of stiffeners to bond flexible layers. They include stainless steel, FR4, polyimide, etc. We can provide 14 layer rigid-flex PCBs in minimum thickness 0.054ʺ and maximum thickness 0.250ʺ. The surface treatment is ENIG, whereas we also provide surface finishes like HASL – leaded and lead free solders, electroless soft gold, electrolytic nickel, immersion silver, carbon ink, etc. We use advanced laser machines, which enable us to deliver accuracy of mil traces, lines, and patterns. The 14 layer rigid-flex PCBs are used in applications such as telecommunication, computers, medical devices, and automobiles.