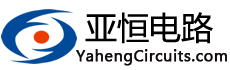

Flexible Printed Circuits Boards

Single layer flexible circuit, up to high layer rigid-flex multilayer PCB, also in combination with HDI and other technologies.

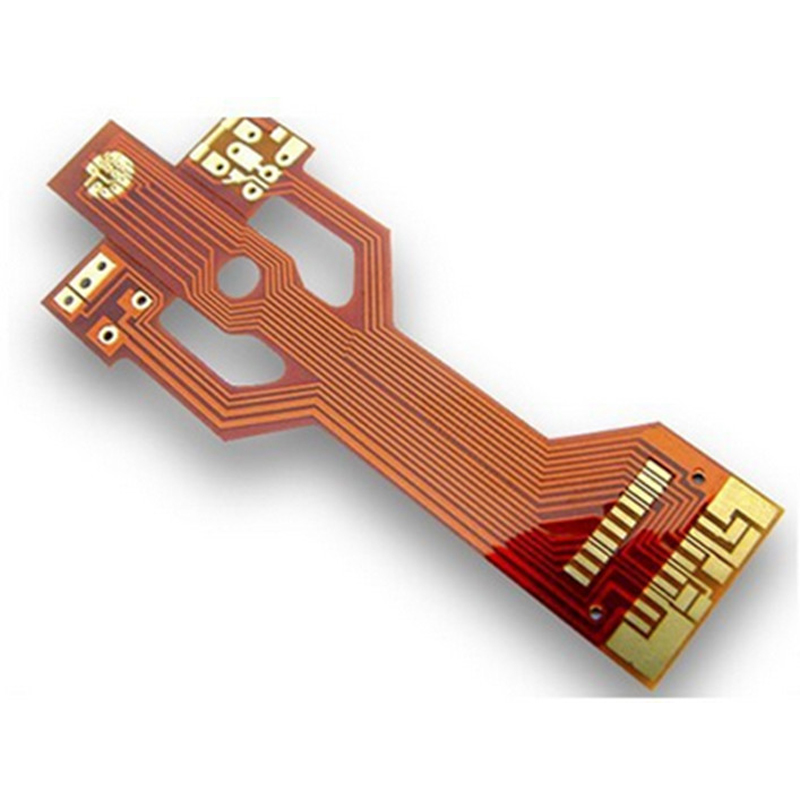

Flexible PCB

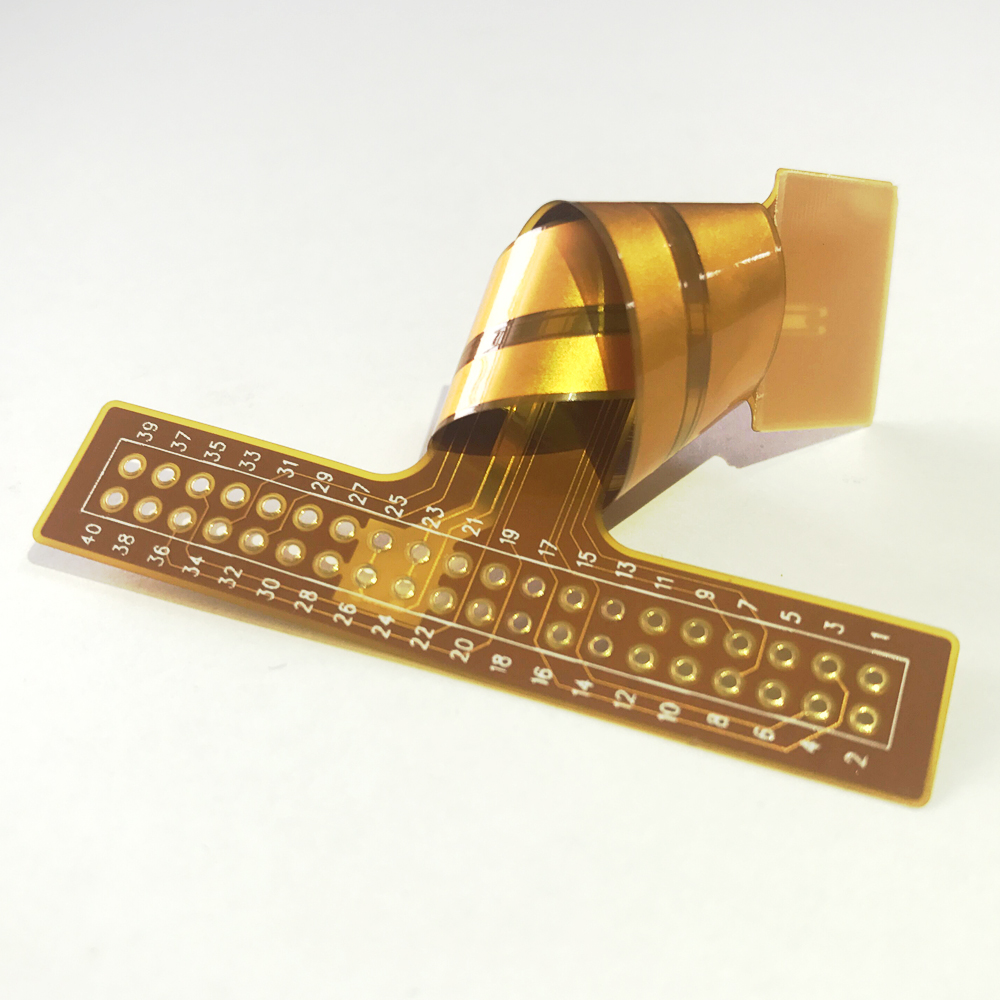

Flexible PCBs are typically manufactured using thin pure polyimide materials and can be single-sided, double-sided or multilayer structures. These can be assigned against the appropriate IPC specifications as:

IPC6013 Type 1 – Single-sided

IPC6013 Type 2 – Double-sided

IPC6013 Type 3 – Multilayer

All types can use stiffeners where rigidity is required and bar single-sided, use PTHs in the same manner as a double sided or multilayer PCB as previously detailed.

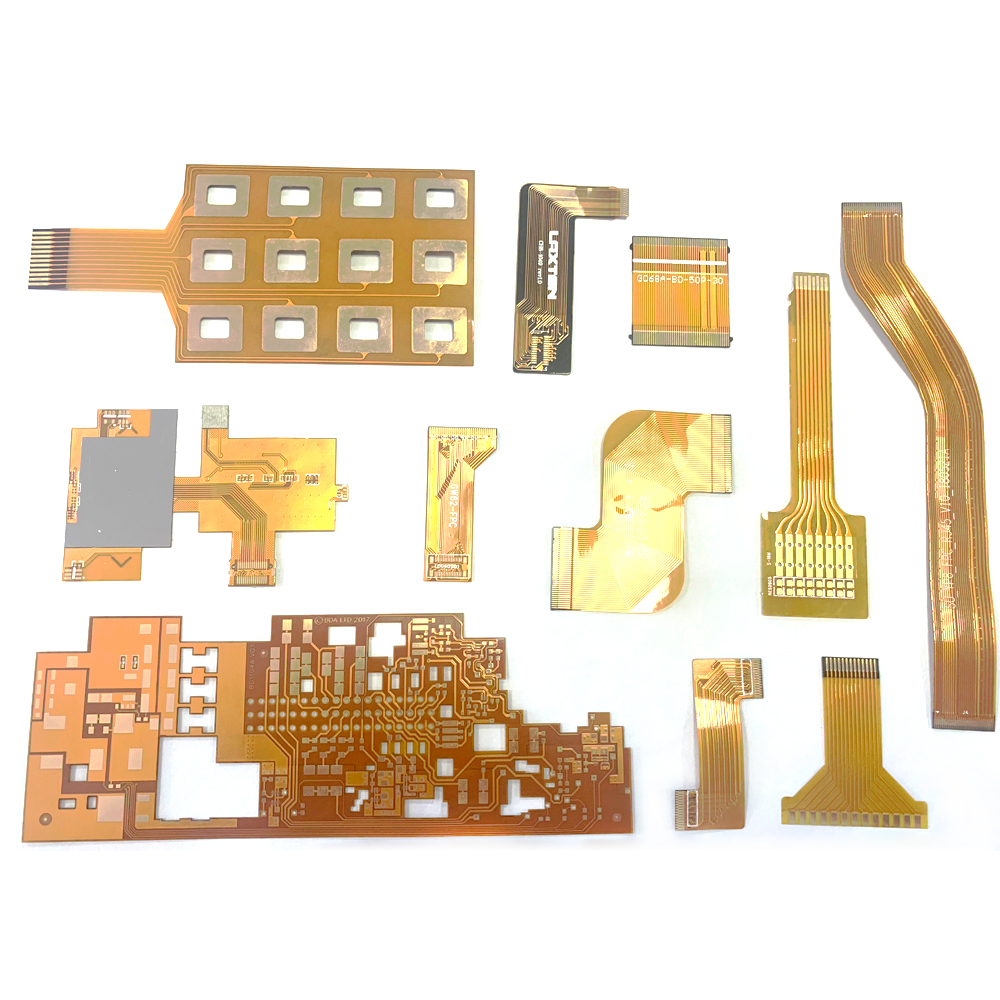

Flexible PCBs facilitate almost complete design freedom and can be bent, twisted or formed to minimise size and space. With a reduced PCB volume, due to thinner materials, weight can also be reduced – a key reason why these types of circuit are used widely in aviation and space applications.

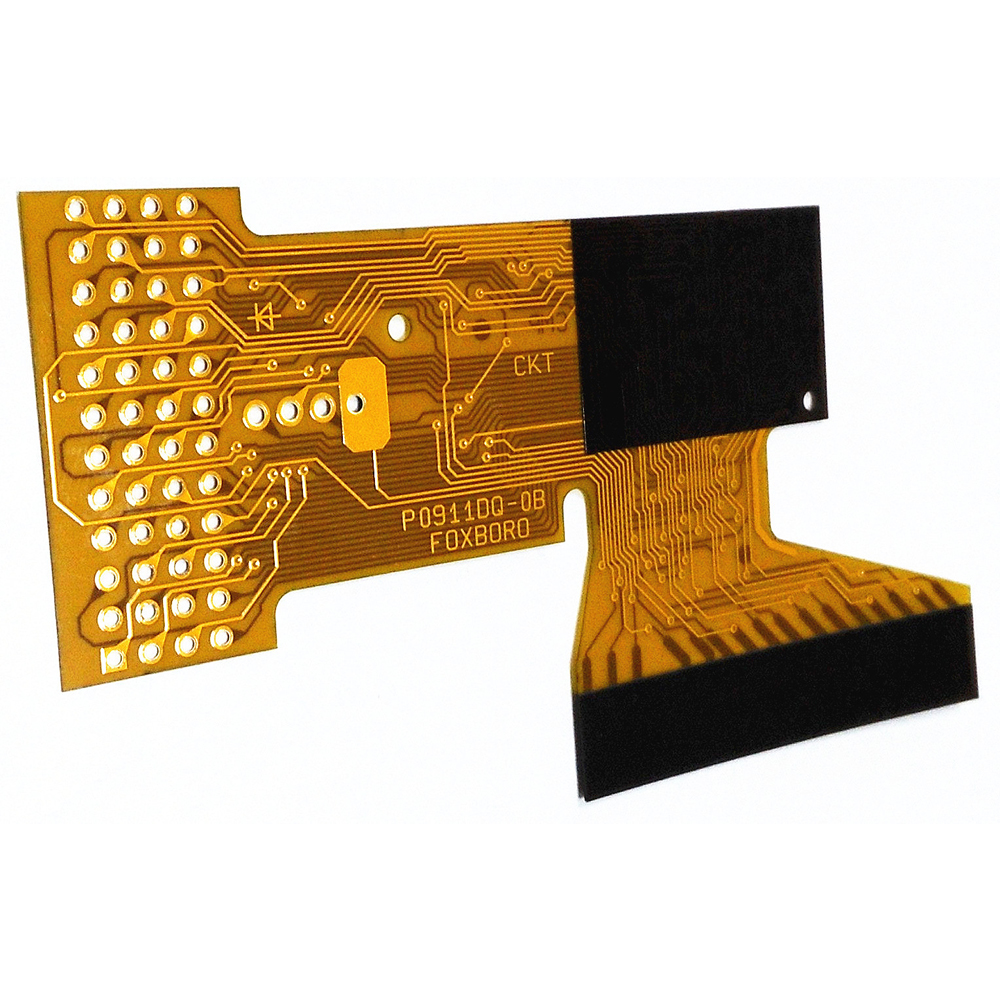

Flexible Printed Circuits Boards made their introduction into the electronics industry as substitutes for cable assemblies. They introduced a number benefits to designers such as reduced weight, reduced size and higher reliability, all at a low cost. As time has passed, the technology has gone through refinement. Today, Flexible PCBs are still used as replacement for cable assemblies, however their scope has evolved to the point of also being able to replace traditional Rigid PCBs. With the ability to mount components based on both SMT and through hole technology, available not only as single sided, but also as double sided THP and Multi-layer technology, flexible PCBs are today utilised in a multitude of applications.

While standard rigid boards have characteristics which make them suited to many applications, the diversity of applications in which electronics is used today has enabled designers to also utilise flexible Printed Circuit Boards as well as hybrid Rigid-Flex Printed Circuit Boards in order to utilise the best PCB technology commercially available for each application.

Today Flexible Printed Circuit Boards are found in the majority of consumer products from computers, where a Flex PCB is used as a cable assembly for hard disk drive heads, to mobile phones, automotive electronics and home entertainment systems just as a starting point.

Yaheng Circuits produces prototype, mid and high volume single sided PCBs, with a copper thickness ranging from 1 to 20 ounces. Operating temperatures range from 130 C to 230 C, depending on base material type. Single sided boards are available with many surface finishes including Organic Surface Protectant (OSP), Immersion Silver, Immersion Tin, Electroless Nickel Immersion Gold (ENIG) and either leaded or lead-free Hot Air Solder Level (HASL).

Yaheng Circuits is not only trying to give customers a good product but also pay attention to offering a complete and safe package. And here we prepare some personalized services for all the orders.

Common packaging:

PCB: Vacuum packaging with carton box

PCBA: ESD packaging with carton box

Shipping:

1.Confirming your shipping address is correct before delivery

2.Orders processed timely after the payment verification

3.Professional package. No worry about goods breakage.

4.Service transit time is upon different carrier, may vary particularly during holiday.