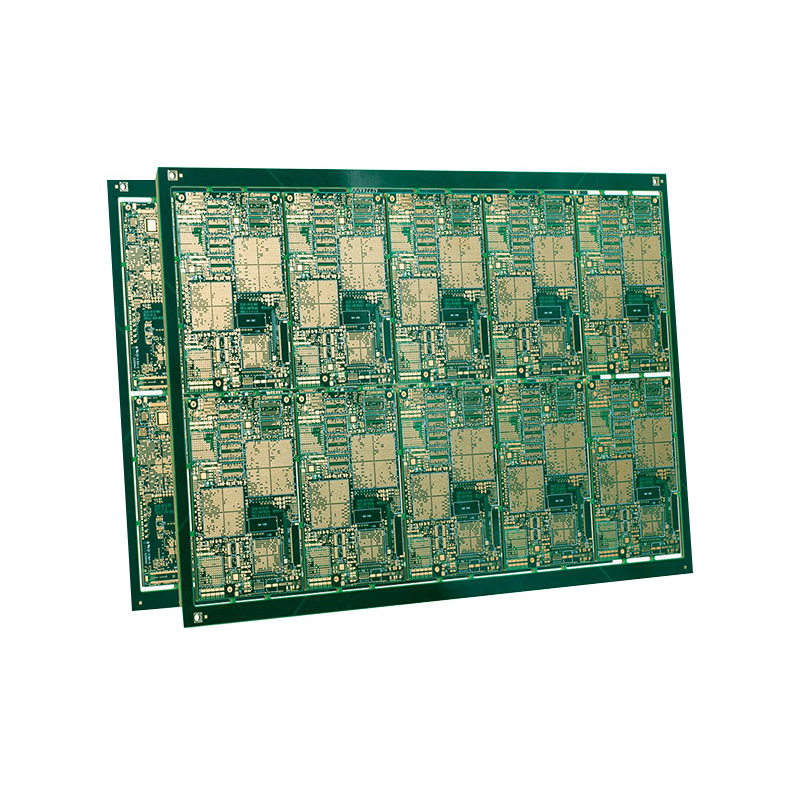

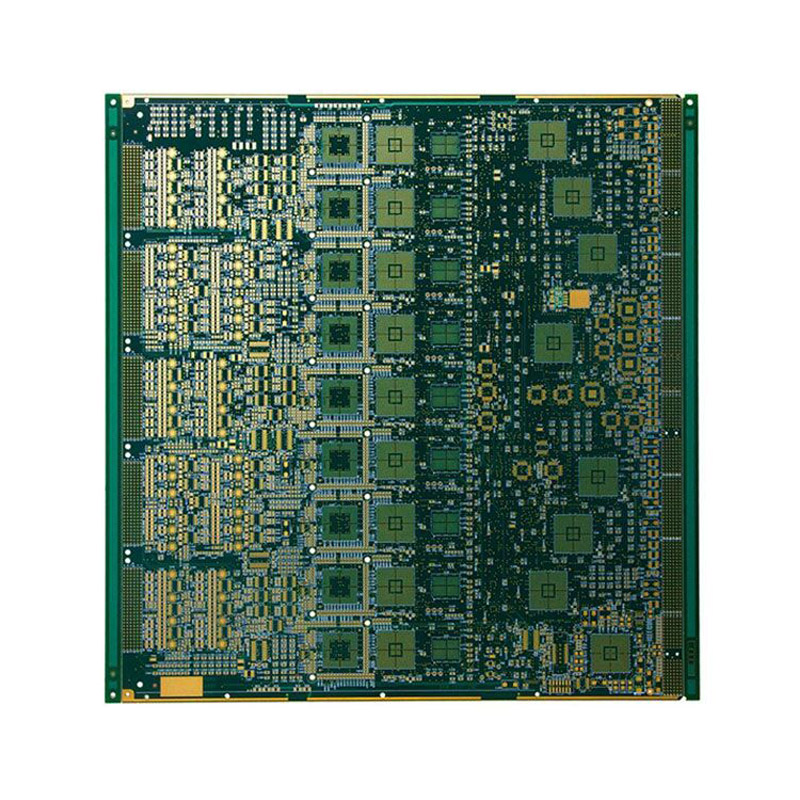

CCTV Camera Rigid Flex PCB circuit board Design

Name : Camera Rigid Flex PCB Cost

Layer count : 6 Layer PCB

Board thickness : 0.9 mm

Copper thickness :1 oz

Fr4 Material: IT180A + AK

Application: Vehicular HD camera

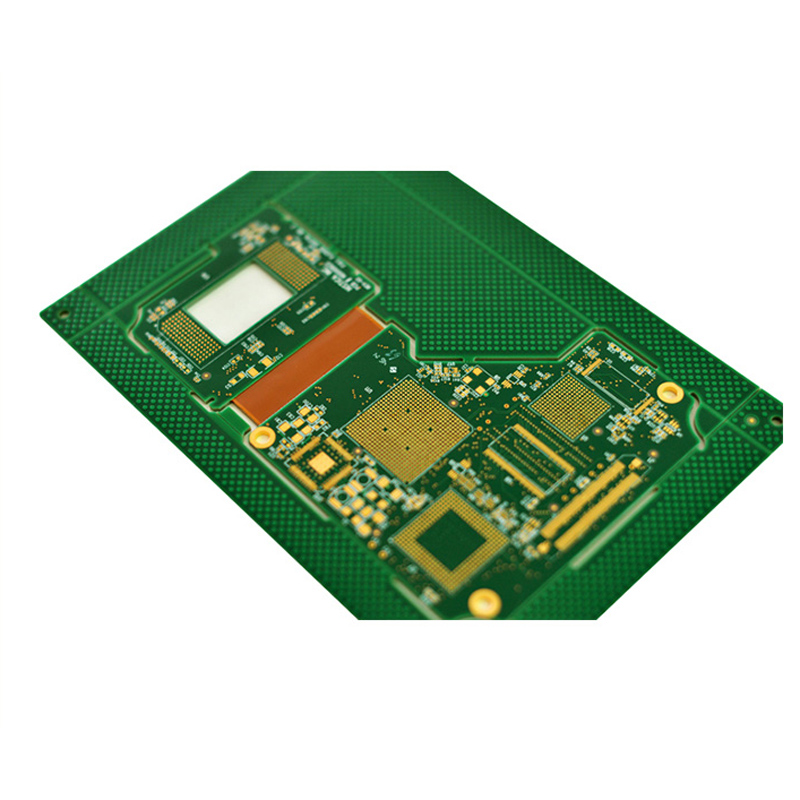

Feature: Rigid-flexible

Closed-circuit television (CCTV) cameras used for video surveillance rely on small, lightweight printed circuit boards (PCBs) to host the image sensor, processor, and interconnect components. Rigid-flex PCB technology is well-suited for integrating the high density functions within the tight space constraints of camera modules.

This article provides an overview of key design considerations for rigid-flex PCBs used in CCTV cameras. We will focus on the layout, materials selection, stackup, and fabrication factors required to ensure reliable performance under mechanical and electrical stresses.

CCTV Camera System Overview

CCTV cameras capture video using a lens that transmits images onto a photosensitive image sensor. Key components include:

Image Sensor – CMOS or CCD sensor that converts light into electrical signals

Lens – Focuses scene onto image sensor; types include fixed, vari-focal, P-iris

Image Processor – Chip processes sensor data into video output format

Flexible PCB – Interconnects sensor to processor board

Memory – Buffers video data before transmission

Power Supply – Provides regulated voltages to components

These subsystems are packaged into compact camera modules rugged enough for harsh environments.

Benefits of Rigid-Flex PCBs for CCTV Cameras

Rigid-flex PCBs provide several benefits for CCTV camera applications:

Compact integration – Interconnect various rigid PCB assemblies flexibly

Layer flexibility – Optimize trace routing using multiple rigid/flex layers

3D configuration – Route traces on multiple axes efficiently

Reliability – Withstand vibration/shock without solder cracks

Serviceability – Allow disassembly to service/replace modules

Signal integrity – Carefully match impedances for video signals

High speed support – Facilitate fast data interfaces like MIPI

Thermal dissipation – Sink heat using thermally conductive rigid sections

Rigid-flex integration enables packaging innovations not possible with rigid PCBs alone.

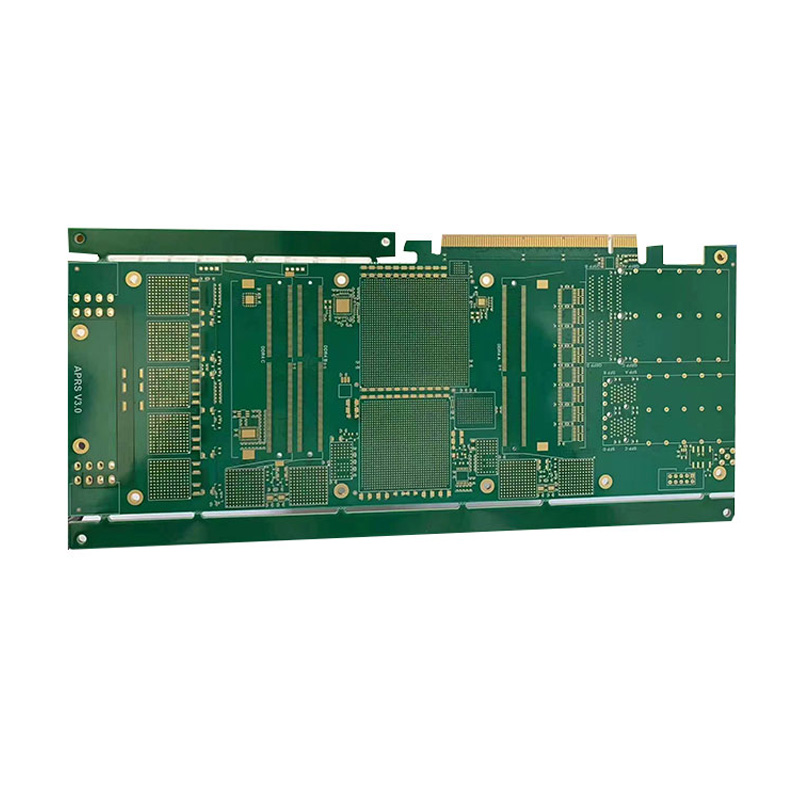

CCTV Camera Rigid-Flex PCB Design Considerations

Here are some of the major design aspects and challenges for rigid-flex PCBs used in CCTV cameras:

Electrical Interface Planning

Sensor selection influences resolution, pixel formats, and data rates

Processor determines video compression methods used

Memory capacities depend on video buffering needs

High speed serial interfaces like MIPI CSI-2 require impedance control

Routing Complexity

Route sensor inputs to processor via flexible layers

Fan-out GPU outputs to numerous memory ICs

Creative use of rigid-flex layers avoids congestion

Layer Stackup

Optimize stackup for routing needs balancing rigidity, flexibility

Ensur

Stackup Configuration Guidelines

Here are some stackup configuration guidelines for CCTV camera rigid-flex PCB layout:

Signal reference planes – Embed ground layers adjacent to critical high speed interfaces for controlled impedance

Balance layer counts – Maintain symmetry of dielectric layers through cross-section to minimize warpage

Interface isolation – Assign separate ground returns for isolated digital and analog domains

Controlled impedances – Match trace widths and spacings to dielectric materials to achieve 50/100 Ohm differential impedances

Power integrity – Incorporate power and ground planes to supply clean, regulated voltages with decoupling capacitors

Reduce crosstalk – Provide ground/power isolation between noisy circuits and sensitive analog traces

Bend radius – Ensure minimum flexible circuit bend radius ≥ 10X material thickness

Reliability – Model stresses and validate design margins through simulation

Careful stackup design ensures signal and power integrity while withstanding stresses.

Fabrication Process Considerations

Fabricating reliable rigid flex PCBs for CCTV cameras involves precision in key process steps:

Lamination

Eliminate voids between rigid and flex layers

Apply uniform pressure and temperature to bond layers

Address resin starvation issues around thick copper shapes

Drilling

Tight depth control for holes spanning multiple sections

Excellent hit-to-hole registration on dense designs

Avoid smear generation compromising hole walls

Routing

Precise depth control maintaining target stackup

Minimize undercuts violating trace spacing rules

Smooth copper foil surfaces; no folds or wrinkles

Plating

Uniform copper plating distribution inside holes

Good throwing power on high aspect ratio micro-vias

Validate hole wall plating integrity through cross-sectioning

Etching

Tight process control for 5 mil line widths

Eliminate opens or shorts violating tolerances

Anisotropic etching on flexible circuits

Soldermask

LPI photosensitive coatings for fine features

Eliminate voids, gaps or alignment issues

Proper curing to avoid outgassing or delamination

A rigorous fabrication process focus enables building high reliability rigid flex boards.

PCB Design Guidelines

Here are some key PCB design guidelines to ensure CCTV camera rigid flex manufacturability and reliability:

Maintain minimum bend radius ≥ 10X flex material thickness

Eliminate acute angles; use teardrops when unavoidable

Allow tolerances for hole positions spanning rigid-flex areas

Check impact of hole densities on alignment accuracy

Ensure stackup construction is within lamination capabilities

Watch for trapped resin around thick copper shapes

Model thermal expansion mismatch stresses using FEA

Verify electrical performance under dynamic flexing

Reviews with the manufacturer during design validation phases prevents issues afterwards.

Testing and Inspection

Testing rigid flex PCBs for CCTV cameras involves:

Pre-Treatment Testing

Microsection internal layers to validate fabrication quality

C-SAM inspection for delamination or interface gaps

Cross-section plated holes to check hole wall plating

Post-Etch Testing

Verify electrical connectivity between layers catches any shorts

Impedance testing of controlled impedance interfaces

Check hole registration accuracy using flying probe testing

Post Soldermask Testing

AOI scan checks soldermask and legend quality

Detect spacing violations or misregistrations

Post-Assembly Testing

Validate video signal integrity and bit error rates pre and post flexing

Environmental stress testing of populated assembly

Life cycle flexure testing for robustness

Rigorous testing at multiple stages ensures quality and reliability.

Conclusion

Rigid flex PCBs provide an enabling packaging solution for integrating the image sensor, processor, memory and interconnects within the tight confines of CCTV camera modules. The combination of rigid sections and dynamic flex layers facilitates routing complexity and 3D configurations not possible with rigid technology alone.

Careful design practices including matching controlled impedances, managing signal isolation, allowance for mechanical stresses, and design-for-manufacturing verification with fabrication partners are vital to ensure reliable performance in demanding conditions. With reliable PCBs, CCTV cameras can capture high quality video securely.

Frequently Asked Questions

Q: What are the main benefits of using rigid-flex PCBs in CCTV cameras?

Rigid-flex PCBs enable creative packaging integration and interconnect within tight spaces while resisting dynamic bending stresses better than rigid PCBs.

Q: What are some key electrical interfaces used in CCTV cameras?

High speed serial interfaces like MIPI CSI-2 are used between image sensors and processors. DDR3/4 memory interfaces support video buffering. HDMI, SDI outputs connect to displays.

Q: What are important design factors from a signal integrity standpoint?

Matching trace geometries to achieve 50 Ohm controlled impedances, isolating analog/digital signals, and minimizing discontinuities is vital for signal integrity.

Q: What fabrication processes need specific attention?

Steps like lamination, drilling, plating, etching and soldermask application require precision when working with thin materials spanning rigid-flex PCBs.

Q: What testing validates the quality and reliability of finished boards?

Pre-treatment inspections, post-etch electrical testing, AOI checks, and post-assembly validation testing provides full quality assurance.