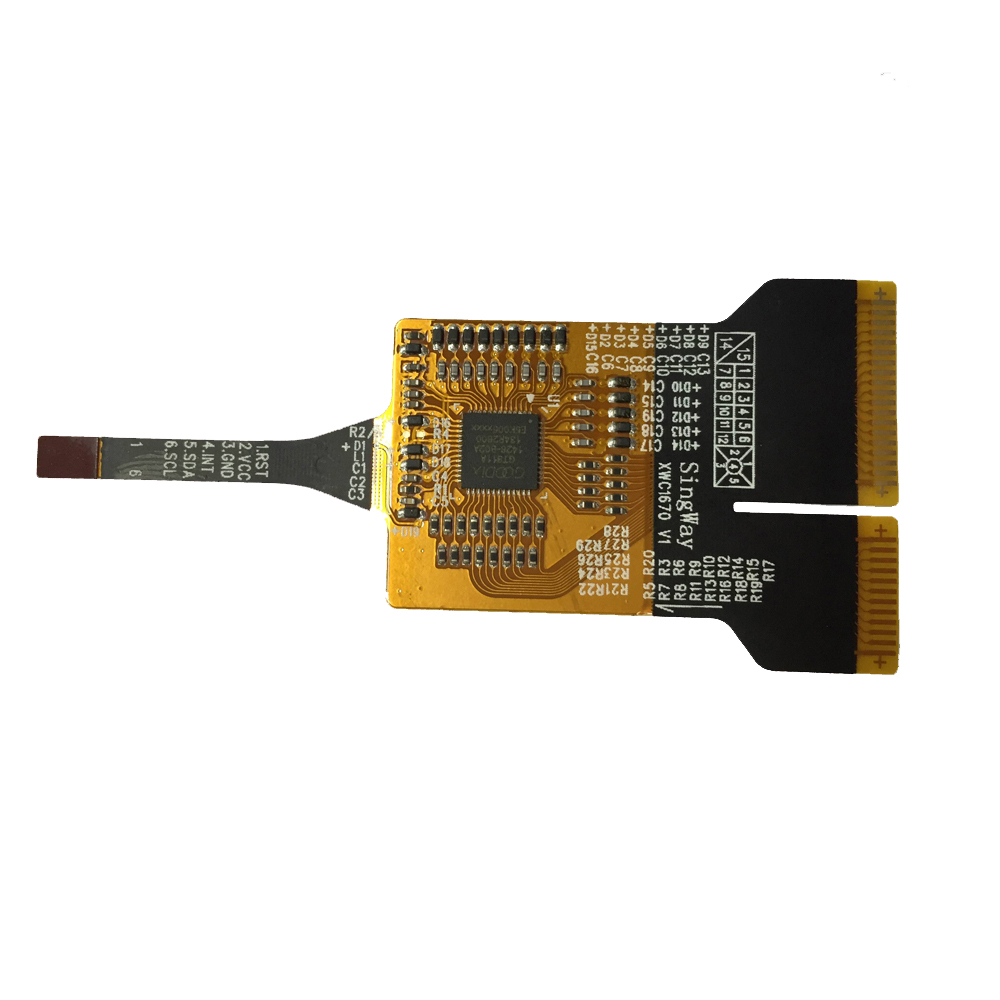

Rigid Flex PCB

Rigid Flex PCB

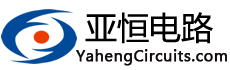

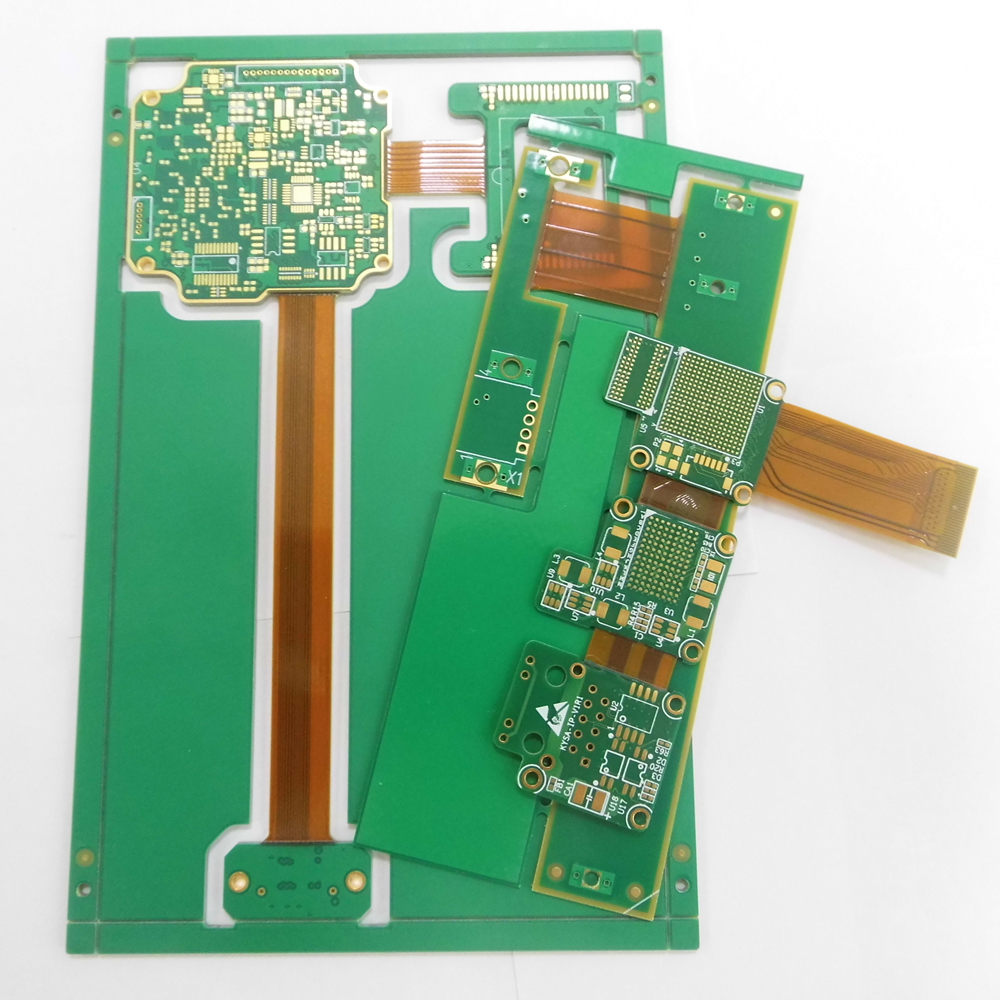

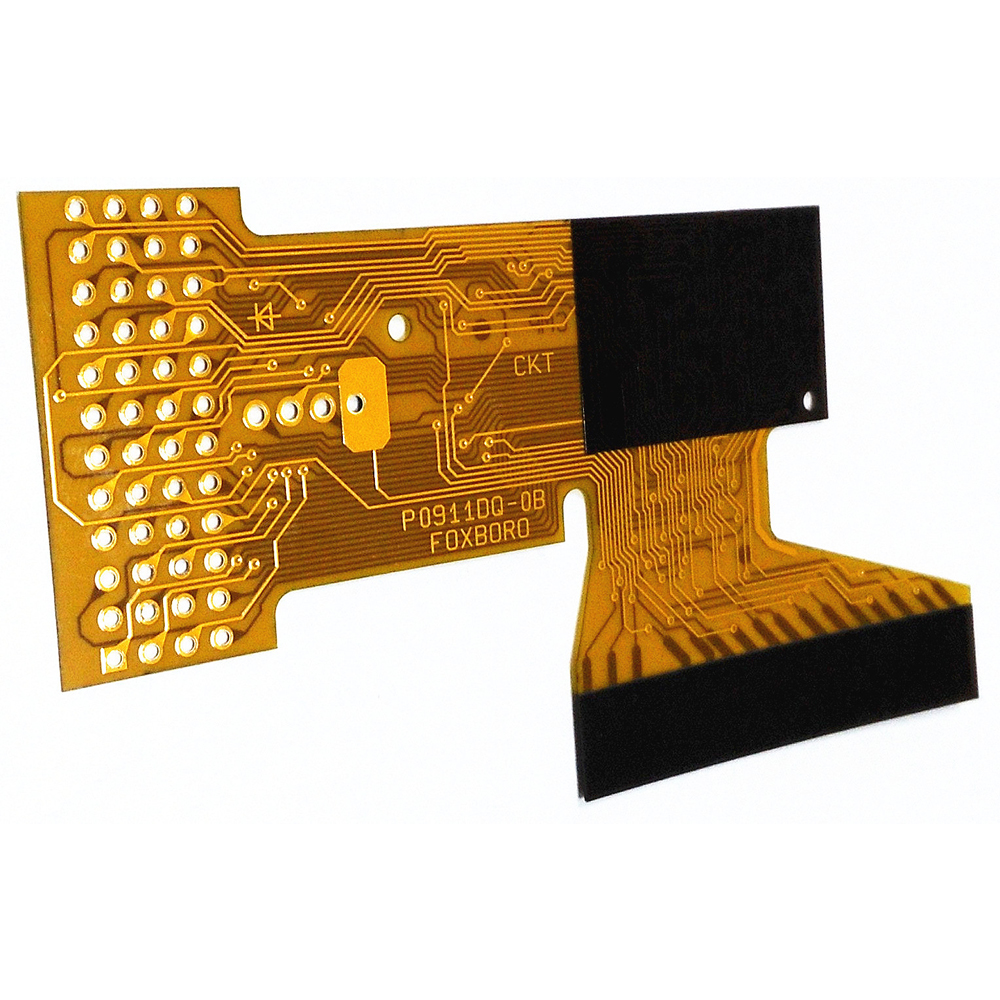

Rigid Flex PCBs, by definition, are a combination of a rigid part(s) joined by interconnecting flex areas where the flex material is used across the entire PCB area. The rigid parts are where there is no bending requirement. Again, PTHs take connections from layer to layer as required. Rigid flex may also employ other technologies as required eg. HDI.

Rigid flex can be used to eliminate or greatly reduce requirements for bulky and costly cable harnesses, in turn taking out cost and reducing assembly time. Like the pure flexible PCBs, these are widely used in aviation and space applications – and also in automotive and test equipment.

We can also supply semi-flex technology solutions.

With incremental increases in complexity and costing, this layer build can be increased to designs incorporating numerous layers within the rigid sections and numerous layers within the flexible section.

Advantages of Rigid-Flexible Printed Circuit Boards:

Mechanical Flexibility: Rigid-Flex technology can be used to manufacture an assembly consisting of two or more Rigid PCBs functionally joined via flexible sections. This configuration replaces the traditional alternative of individual rigid PCBs joined by external cables/wires. The solution provides for an integrated, high reliability PCB, with mechanical flexibility and controlled impendance across the whole board, including the flexible interconnection board.

Reduced size and weight: This hybrid technology allows for the miniaturisation of a design in a number of ways. Firstly it allows for the PCB to be designed on a multidimensional level, rather than just a flat plane. This allows the PCB to be more efficiently designed to fit into a 3 dimensional space. Secondly as the flexible PCB component does away with interconnection, cables and plugs can be reduced or eliminated, saving both PCB real estate and connector volumetric space.

Reduction of connectors: By integrating the flexible PCB into the rigid PCB, a Flexible pcb tail can protrude out of the rigid pcb area and be used as a cable for both power and signal, to and from the main rigid PCB area. Apart from the reduction of components and effective space required, the flexible section can offer shielded, impedance controlled inter-connectivity, which is difficult to achieve using alternate technologies.

Shock and vibration: Since the flexible section of the assembly is bonded to the rigid section, and the flexible section has low mass with good ductile properties, Rigid-Flex assemblies are not only suitable for environments which expose the product to shock and vibration, but also provide a solution which can provide an increased level of reliability as compared to conventional solutions.

Low Cost: By reducing component count and hence manufacturing costs, the increased cost of this PCB can often be compensated for by these savings. When the added considerations of reliability, reduced space and increased performance are added to the equation, Rigid-Flex boards are often found to be the lowest cost solution for a diversity of applications.

Conclusion:

Rigid-Flexible PCBs provide a new dimension of possibilities to electronic designers. This technology gives designers a new way to solve many of the design issues which are inherent with electronic design and the interconnections between circuit boards and the outside world. In addition they allow designers to address problems which were otherwise un-resolvable.

Yaheng Circuits produces prototype, mid and high volume single sided PCBs, with a copper thickness ranging from 1 to 20 ounces. Operating temperatures range from 130 C to 230 C, depending on base material type. Single sided boards are available with many surface finishes including Organic Surface Protectant (OSP), Immersion Silver, Immersion Tin, Electroless Nickel Immersion Gold (ENIG) and either leaded or lead-free Hot Air Solder Level (HASL).

Yaheng Circuits is not only trying to give customers a good product but also pay attention to offering a complete and safe package. And here we prepare some personalized services for all the orders.

Common packaging:

PCB: Vacuum packaging with carton box

PCBA: ESD packaging with carton box

Shipping:

1.Confirming your shipping address is correct before delivery

2.Orders processed timely after the payment verification

3.Professional package. No worry about goods breakage.

4.Service transit time is upon different carrier, may vary particularly during holiday.